PROCESS

1. Pickling Process

Pickling is a method of preparing metal surfaces by chemical reaction, electrolysis, or both. In pickling, rust and scales are removed by chemical reactions with mineral acids and with certain alkaline materials

2. Phosphating Process

Phosphating is a chemical method of surface treatment in which a metallic surface reacts with an aqueous phosphate solution. This creates a hardly soluble conversion layer made of metal phosphates. For this purpose, the material is first cleaned in pickling process and then the phosphate layer is formed.

3. Spherodized Annealing Process:

Spherodized annealing is the term that describes a thermal process which results in a globular or spheroidal type of carbide after heating and cooling. There are several types of spheroidize cycles. Spherodized annealing is generally done on parts which have been work hardened, to allow them to be further worked, either rolled in the case of coils, or drawn for wire. This resulting product has improved ductility and toughness with reduced hardness and strength. Spherodized annealing is carried out under a protective (endothermic) atmosphere to prevent oxidation and decarburization.

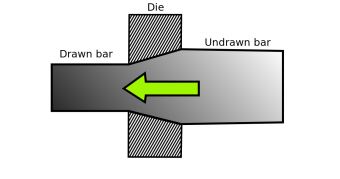

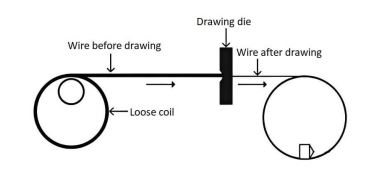

4. Drawing Process: (Coil/Bar Shape)

Wire drawing is a cold plastic deformation process by which the diameter of a rod or a wire is reduced and its length is increased by pulling the workpiece through a calibrated hole of a conical die. The products are characterised by high strength because of strain hard

Bright Bars are produced by using the process of cold drawing, centerless grinding, peeling, shaving, turning, or a combination of these processes. As a result, it has better dimensional accuracy, smooth surface, straightness and is usually free from surface defects.